KASKAL FAÇADE TESTING CENTRE

KASKAL has constructed the most advanced facade testing facility available for commercial use in Southeast Asia

Having been involved in the facade industry for quite some time, KASKAL understands the need for an efficient, flexible and modern approach to carry out testing. Whilst designed to undertake the testing of very large facade samples, we are also able to carry out much smaller requirements including window and door systems, all at very competitive service rates.

KASKAL Façade testing facility was commissioned on January of 2010 and since then, Kaskal has been conducting PMU testing for local and overseas projects.

KASKAL Façade testing Centre is the first façade testing laboratory in Thailand to be accredited with ISO/IEC 17025 “General requirements for the competence of testing and calibration laboratories” in June 2018.

TESTING

Air Penetration Test

Air is supplied or exhausted from the chamber at the rate required to maintain the specified pressure difference across the specimen. It is assumed to be equivalent to the air leakage through the specimen.

Water Penetration Test By Static or Cyclic Air Pressure Difference

Air is supplied or exhausted from the chamber at the rate required to maintain the specified pressure difference across the specimen, while spraying water onto the outdoor face of the specimen at the required rate and any water penetration is observed.

Water Penetration Testing (AAMA 501.1-17) By Dynamic Wind Pressure

Apply the specified dynamic wind stream along with the specified water spray for a period of not less than 15 minutes. Any water leakage occurring during the period of testing shall be noted and reported, stating both the location and quantity of the leakage.

Structural Performance Testing – Wind Pressure Test By Static Air Pressure

Supply air to or exhaust air from the chamber according to a specific loading program, at the rate required to maintain the test pressure difference across the specimen. Observe, measure, record the deflection, deformation, and nature or any distress or failures of the specimen.

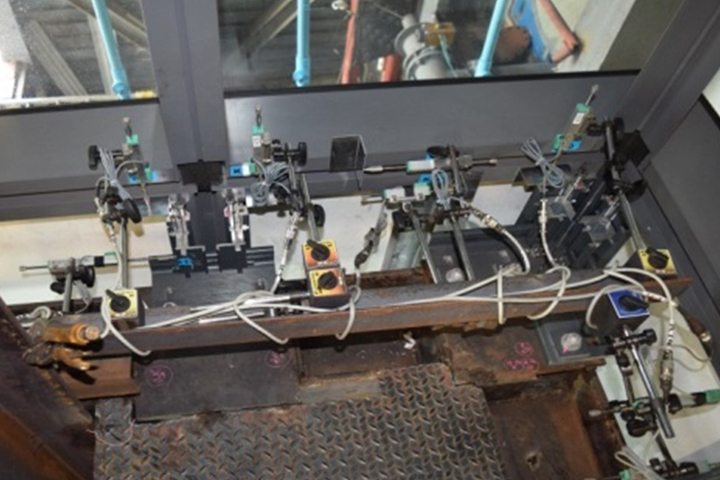

Building Movement Testing (Static & Cyclic Movement) By AAMA 501.4 & AAMA501.7 (Horizontal & Vertical Movement) AS/NZS 4284:2008

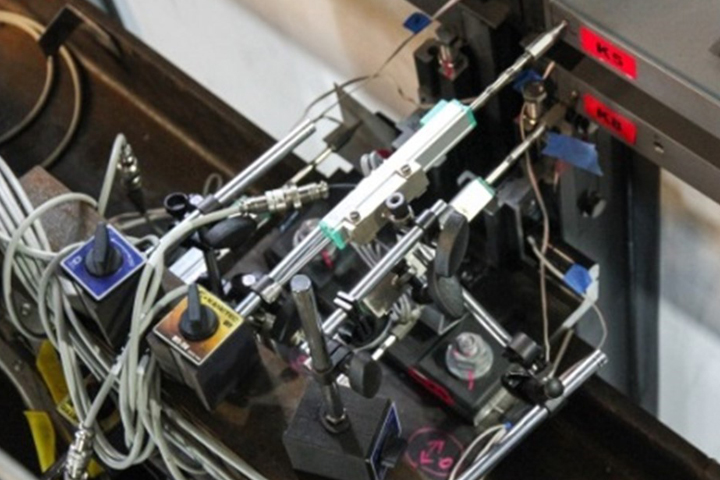

Test chamber structure subjecting to story-drift displacements simulating the response of building due to in-plane movement. The procedure involved cyclically displacing the moveable steel beam to a designated displacement at a uniform displacement, and to repeatedly cycle as required. Movement was controlled using hydraulic directional valve operating under displacement control. Observe and record any distress or failures of the specimen.